Quality control in textile contract manufacturing is a critical process to ensure products meet established standards. Effective quality control protects brand reputation and reduces return rates.

Quality Control Stages

Raw Material Inspection

Quality control of fabrics and accessories. Fabric weight, color, durability, and defect inspection are performed at this stage.

In-Line Inspection

Periodic controls during the production process evaluating sewing quality, size compliance, and workmanship.

Final Inspection

Comprehensive control after production completion using AQL standard random sampling.

What is AQL (Acceptable Quality Level)?

AQL is an international standard that determines the acceptable quality level. In textiles, AQL 2.5 or 4.0 is generally applied.

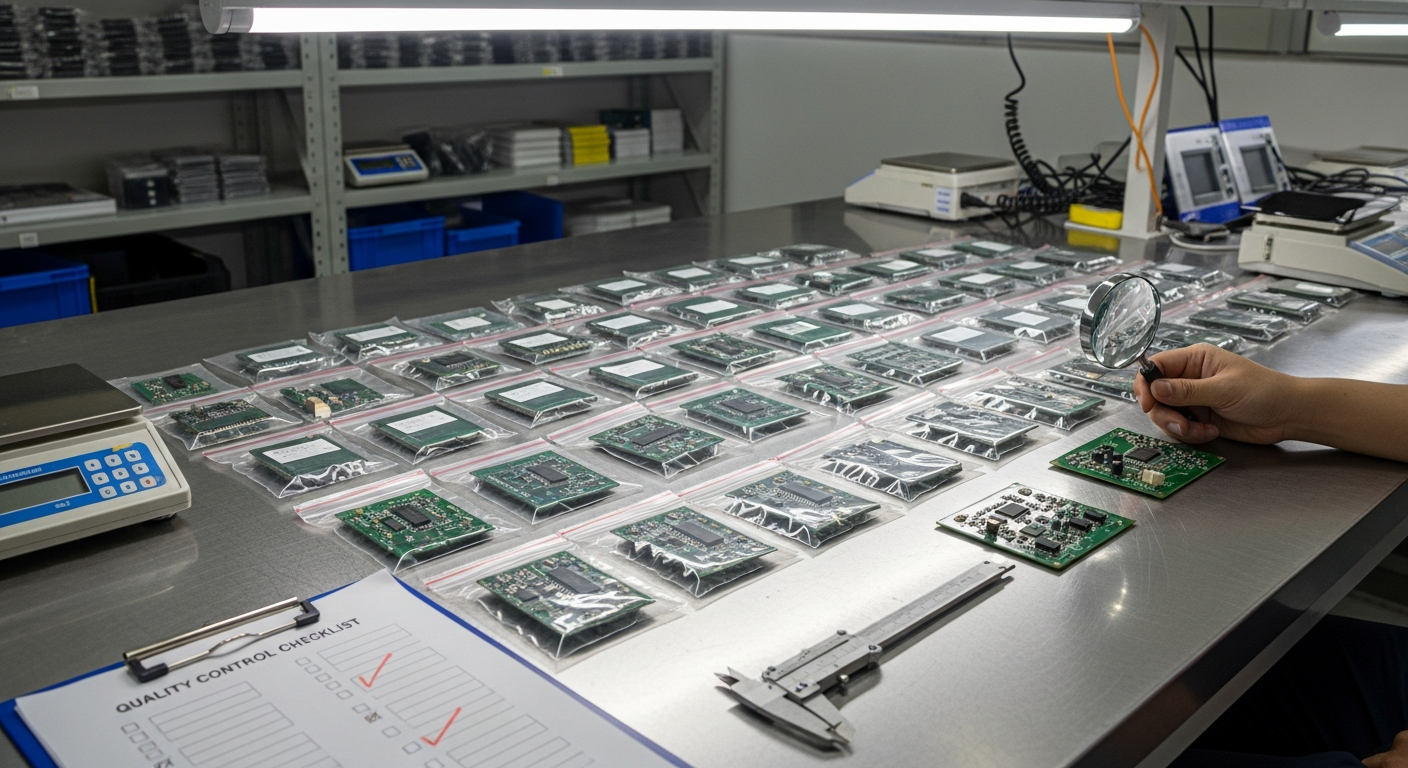

Quality Control Checklist

- Size control (all sizes)

- Sewing quality inspection

- Fabric defect inspection

- Color matching control

- Accessory and label inspection

- Care label compliance

- Packaging quality control

- Metal detector test

For more on textile manufacturing, see Textile Manufacturing Guide, Garment Manufacturing, and Manufacturing Processes.